The increasing use of data centers, which serve as digital infrastructure, helps society as a whole

to save energy, but as the market expands in size, the energy use of the infrastructure itself is

becoming an issue that must be dealt with. The Japanese government’s Green Growth Strategy sets

targets for a wide range of industries, including the following targets for data centers:

• By

2030, all new data centers should achieve 30% energy savings, and data centers should use renewable

energy for a portion of their energy requirements.

• Achieve carbon-neutral data centers by

2040.

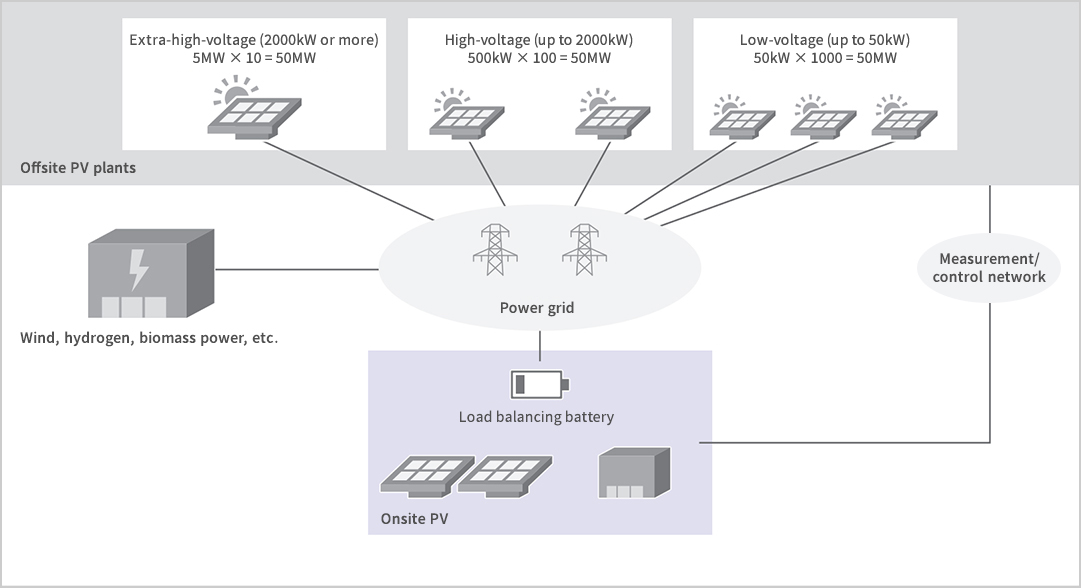

At IIJ, we see efforts to reduce greenhouse gas emissions through the use of renewable energy

and improvements in energy efficiency at data centers, which account for over 70% of our greenhouse

gas emissions (Scope 1 and 2), as a priority, and as such, we have set goals for our efforts as shown

below. We have also acquired the ISO 14001 international standard for environmental management systems

at our own data centers and are working to improve environmental performance, including in terms of

carbon neutrality.

| Measure | Goals |

|---|---|

| Use of renewable energy | We aim to raise our data centers’ (Scope 1 and 2) renewable energy usage rate to 85% by FY2030. |

| Improve energy efficiency | Through ongoing technological innovation out to FY2030, we aim to have the PUE*1 readings of our data centers below the industry ceiling*2. |

*1. PUE (power usage effectiveness): Total data center facility energy consumption / IT equipment energy consumption

*2. Industry PUE ceiling: PUE of 1.4 or lower (as of April 2022, the Agency for Natural Resources and Energy has set the benchmark index and target level for the data center industry to be a PUE of 1.4 or lower; businesses that achieve this are regarded as energy-saving leaders).

Reference: https://www.iij.ad.jp/en/ir/integrated-report/tcfd/

Energy-saving initiatives—outside-air cooling, bus ducts, three-phase four-wire UPS

Here, we discuss the energy-saving technologies we are introducing at IIJ data centers as a means

of achieving carbon neutrality.

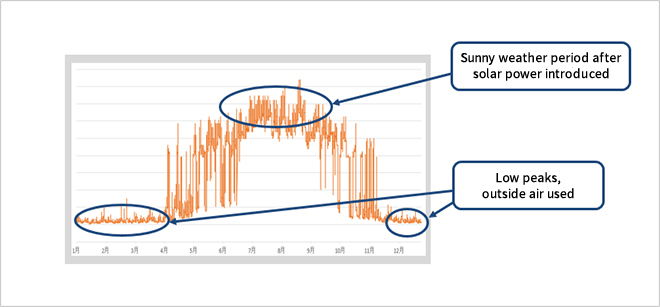

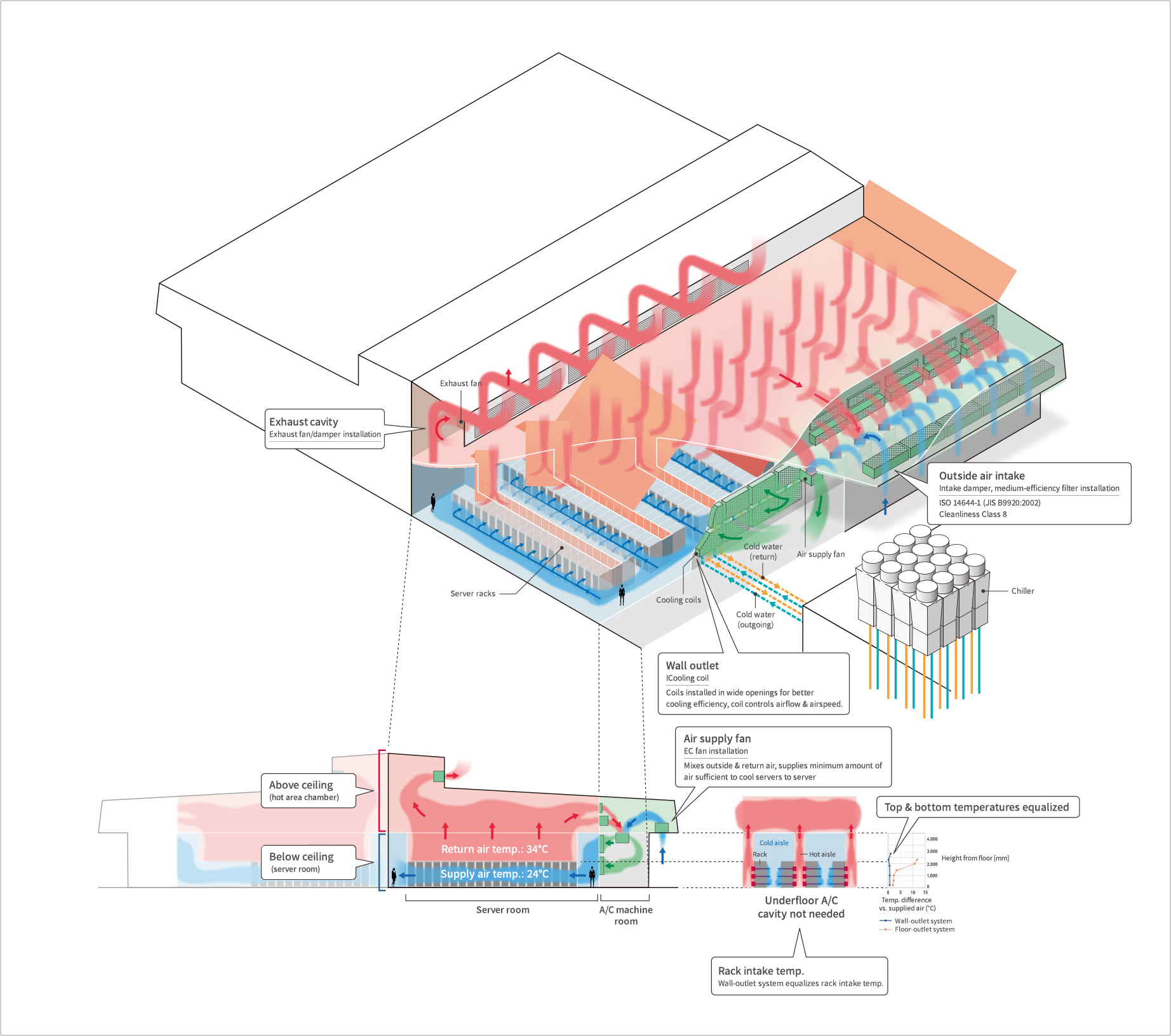

Actively making use of outside air is one potential method of

reducing the energy used in IT equipment cooling, which is the most power-hungry aspect of data

center facilities. Using outside air to cool IT equipment helps to minimize the amount of time the

main energy-consuming equipment (compressors and chillers*) is running. With conventional data

center air-conditioning systems, compressors and/or chillers would run year round, but at IIJ data

centers, we use outside air to cool the IT equipment if the temperature of that outside air is

sufficiently low.

*Compressor: Device used in air-cooled cooling systems. Cools by compressing refrigerant

gas.

Chiller: Device used in water-cooled cooling systems. Cools by circulating cold water and

exchanging heat.

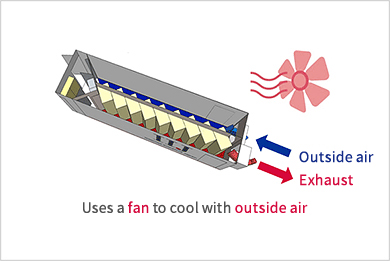

Cooling systems that use outside air can use either direct outside-air cooling or indirect

outside-air cooling. Direct outside-air cooling is more efficient than the indirect method, but

because the outside air comes into direct contact with the IT equipment, air quality and other such

aspects of the environment in which the system is installed must be taken into account. IIJ uses

direct outside-air cooling systems at its Shiroi Data Center Campus and in the air-conditioning

modules on the IT modules (IZmo) at

its Matsue Data Center Park.

Here, we use the air-conditioning modules as an example to explain

the way in which the direct outside-air cooling systems are controlled in order to cool the IT

equipment. Although the temperature and humidity of outside air fluctuate and are thus not constant,

we need to use that outside air to continuously maintain the required temperature and humidity in

the environment in which the IT equipment is installed. The air-conditioning modules have three

operation modes for creating the required temperature and humidity.

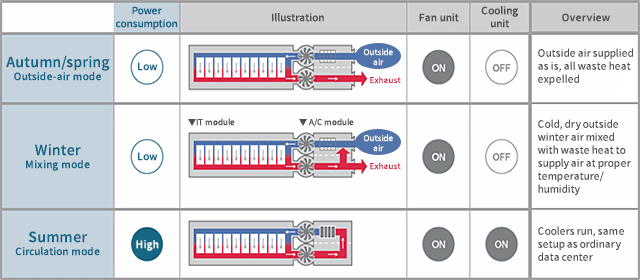

1. Outside air mode

Used when outside air conditions are suitable for cooling IT equipment. The outside air is supplied to the IT equipment intake as is, and the IT equipment waste heat is simply expelled. Only the fans consume power in this mode, so energy-saving performance is high.

2. Mixing mode

Used mainly in winter when it is too cold to supply outside air directly to the IT equipment. IT equipment constantly emits warm exhaust air, so a damper is opened/closed to achieve the right mix of outside air and warm IT equipment exhaust, making the temperature suitable for IT equipment air intake. The only power consumed is that used to run the fans plus a negligible amount for actuating the damper, so this mode has excellent energy-saving performance.

3. Circulation mode

Used mainly in summer when outside air is too hot for IT equipment intake. The air-conditioning module actuates a damper to close the outside air intake and exhaust ports, and runs a compressor. Energy-saving performance is inferior to that in the outside air and mixed modes.

With our co-IZmo/D modules, which integrate air-conditioning and IT equipment into a single unit, our goal was to save even more energy by using a year-round direct outside-air cooling system that manages humidity and temperature using only outside air and without the use of chillers and humidifiers. Our demonstration tests showed that we could reduce air-conditioning power consumption, but the IT equipment consumed more power because of increased fan speed, so while pPUE did improve, our work has also revealed that we need to optimize IT equipment and air-conditioning control if we are to reduce total power consumption.

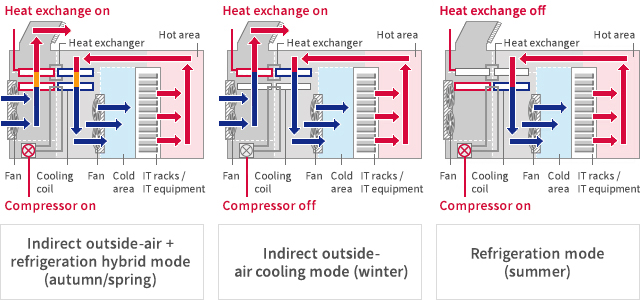

Indirect outside-air cooling is less efficient than the direct method, but it has the advantage of being able to use outside air for cooling even in environments where outside air quality is poor. IIJ uses indirect outside-air cooling on its co-IZmo/I modules integrating IT equipment and air conditioning, and this contributes to the high degree of flexibility co-IZmo/I offers in terms of installation location.

Here, we use the air-conditioning control on co-IZmo/I as an example to explain the way in which the indirect outside-air cooling systems are controlled in order to cool the IT equipment. The basic concept is the same as for the air-conditioning modules that use direct outside-air cooling, with the difference being that a heat exchanger is used to prevent outside air from being drawn directly into the IT equipment.

1. Indirect outside-air mode

Used when the IT equipment can be cooled using outside-air heat exchange only (mainly in winter). The fans are the main power consumers, so energy-saving performance is high.

2. indirect outside-air + refrigeration hybrid mode

Used when the IT equipment cannot be cooled using outside-air heat exchange alone (mainly in autumn/spring). The system runs a compressor but also uses outside air, so power consumption is lower than when cooling using a compressor alone.

3. Circulation mode

Used mainly in summer when outside air is too hot for IT equipment intake.

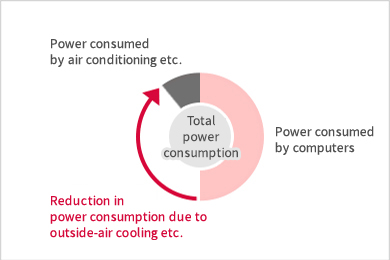

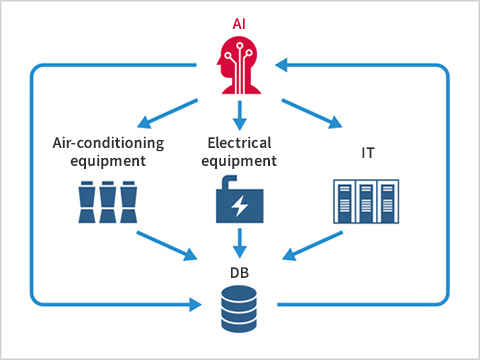

When it comes to cooling IT equipment at IIJ, we endeavor to save energy not only on the hardware front but also via software. One way we are doing this is by using AI for air-conditioning control, which we are testing at Shiroi Data Center Campus. Based on data center conditions, including IT equipment operating status, we use AI to determine optimal air-conditioning settings for the environment. At the current stage, we are accumulating verification data, but ahead, we are looking at tying things in more tightly with the IT equipment and increasing the amount of information that is fed back into the air-conditioning control system so that the control scheme includes the IT equipment side of things as well.

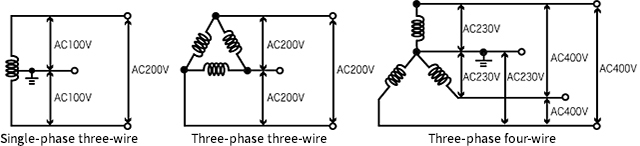

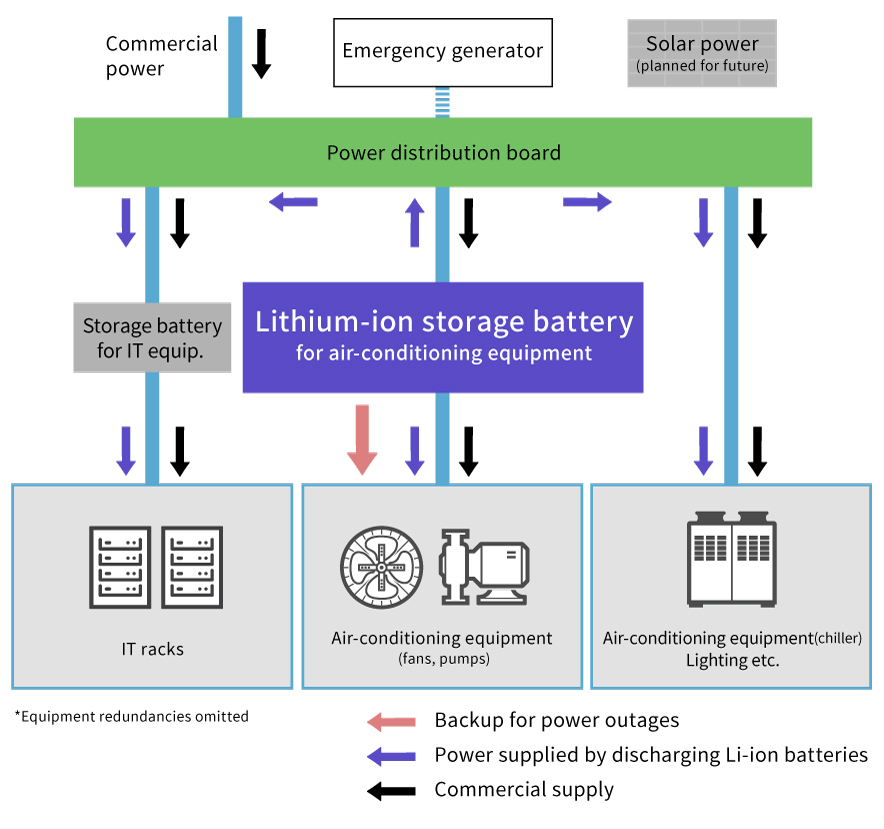

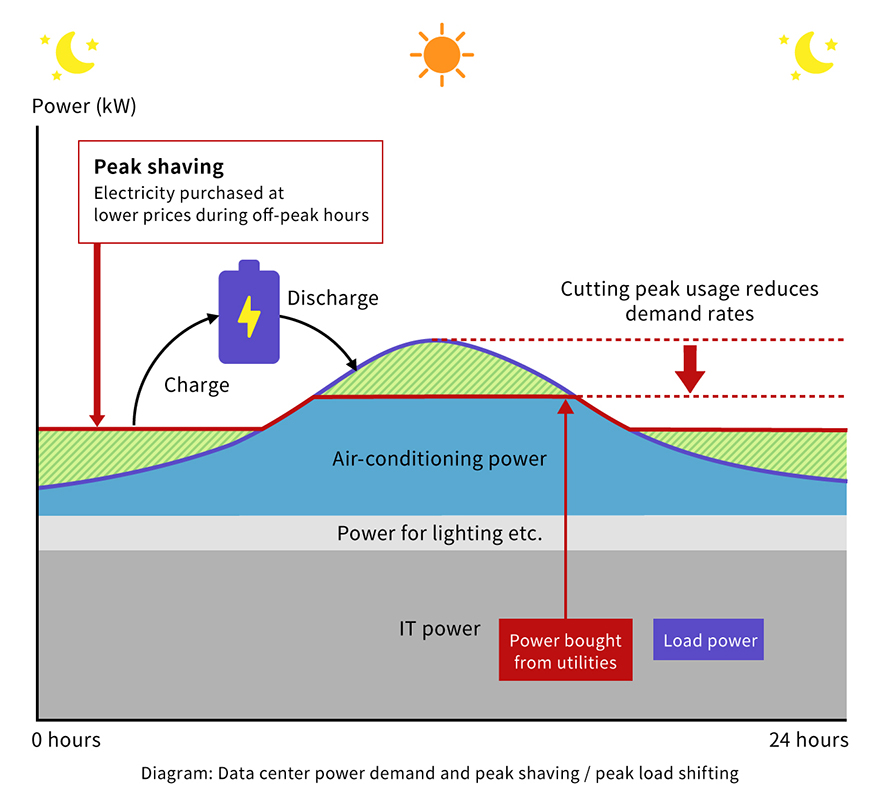

As an energy-saving measure for electrical equipment, we use a three-phase four-wire power distribution system. Conventionally, data centers in Japan have used a 100V AC power supply, as this is the most versatile system available in Japan. Amid the rise of cloud computing, cloud providers have themselves begun to build data center facilities suitable for cloud infrastructure, and it is now possible within such cloud infrastructure facilities to use 200V AC, instead of 100V AC, as standard. To increase efficiency, IIJ has revised its power distribution systems and adopted 200V AC systems throughout Matsue Data Center Park and Shiroi Data Center Campus. This has made it possible to reduce the current flowing through the power delivery paths, enabling us to suppress the voltage drop, increase power supply efficiency, and downsize the power lines. In data centers, UPSs (uninterruptible power systems) are used to provide IT equipment with an uninterrupted high-quality (constant voltage, constant frequency) supply of power. Typical UPS outputs include three-phase three-wire 400V AC and three-phase four-wire 400V AC. Both types of systems output at 400V, but three-phase three-wire systems use a transformer to step down to 100V and 200V AC, the operating voltages of IT equipment, while with three-phase four-wire systems, a 230V AC supply can be pulled directly out. Stepping down using a transformer involves power loss, so three-phase four-wire systems offer better power supply efficiency. Three-phase four-wire systems are widely used in data centers overseas and are now increasingly being adopted in data centers in Japan. IIJ was a first-mover in Japan with the use of three-phase four-wire systems on IZmo ver. 2 (November 2013) modules at Matuse Data Center Park, and it has adopted such systems at Shiroi Data Center Campus as well.

One metric for measuring how efficiently a data center uses power is PUE*, with a PUE reading closer to 1.0 indicating better efficiency. Matsue Data Center Park has a PUE in the 1.2 range and Shiroi Data Center Campus is designed for a PUE in the 1.2 range. Japan’s Act on the Rational Use of Energy (the “Energy Saving Act”) was revised in 2022 to add data centers to the list of industries subject to its benchmark system, with a benchmark target of a PUE of 1.4 or lower being set, so both data centers can be considered highly energy efficient in this sense.

*PUE is found by dividing a data center’s total power consumption by the power consumption of its IT equipment (servers and the like). The more power consumed by air-conditioning systems for cooling and the like, the higher the PUE reading.