Top of Page

- Links to move inside this page.

- HOME

- About IIJ

- News / CSR

- Press Releases

- 2020

- IIJ builds IoT system for new production line at Toyota Motor Hokkaido

IIJ builds IoT system for new production line at Toyota Motor Hokkaido

Offering a single-source solution for everything from design, operational data collection, and storage to a platform for data visualization and analysis

August 3, 2020

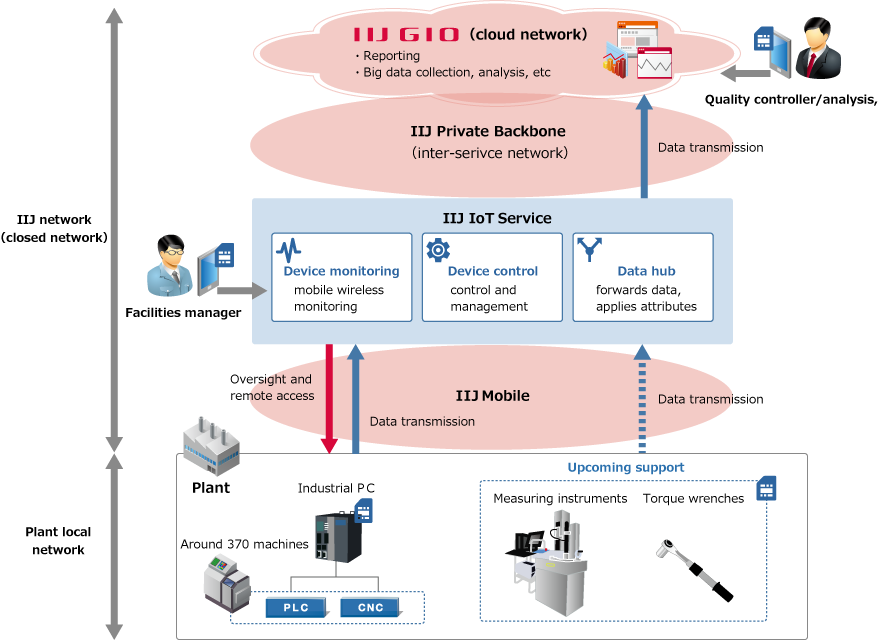

TOKYO-August 3, 2020-Internet Initiative Japan Inc. (IIJ, TSE1: 3774), one of Japan's leading Internet access and comprehensive network solutions providers, today announced that it has built an Internet of Things (IoT) system for a new production line at Toyota Motor Hokkaido Inc. (hereafter, TMH; HQ: Tomakomai, Hokkaido; President: Yasuo Hojo) that produces the drive units installed in the new Yaris car model. With this IoT system, IIJ provides a one-stop solution for everything from data collection via a closed mobile network from PLC(*1), CNC(*2), and other control devices on the production line to the creation of a cloud platform for visualizing and analyzing those collected data. Building out this IoT system to all processing and assembly production lines is a cutting-edge initiative for TMH.

- (*1)PLC (programmable logic controller):An industrial computer that automatically controls the machinery of a production line according to the programs loaded into it.

- (*2)CNC (computerized numerical control):A device that automatically controls the rotation speed, cutting speed, movement distance, and other parameters of a machine tool, based on inputted numerical instructions.

Background to Implementing IoT

TMH develops the technology for various automotive drive units, such as automatic transaxles, continuously variable transaxles (CVTs), and hybrid transaxles, and it manufactures and supplies these both within Japan and abroad. The company installed an IoT system on its production line for processing and assembling hybrid transaxles, a key component in improving the fuel performance of hybrid vehicles. The system began operations in December 2019, helping to triple production volume.

The installation of a new line has often entailed the following kinds of demands for quality and productivity management improvements, leading to the introduction of IoT systems to better visualize and analyze the status of plant equipment.

- Obtain more operating information about plant equipment, and gather and compile data from measuring equipment and other various disparate sources, to build a data platform for visualization and analysis

- Visualize the current state of equipment as the first step towards the future goal of achieving autonomous equipment that can run automatically and repair itself, using feedback such as data analysis results to predict equipment failure warning signs and optimize part replacement time.

Features of the Installed IoT System

- Quick delivery and avoiding any impact on existing networks with its own closed mobile network

Industrial PCs with mobile communications features were retrofitted to the production line, and IIJ built an IoT-dedicated network for data collection and remote access using mobile communications of the IIJ IoT service. The use of a mobile network avoids any impact on existing information networks and avoids the need for routing cable through a plant, making it possible to set up at a lower cost and short times. In addition, this provides a dedicated private cloud using a closed network for all communications between industrial PCs and the cloud, and it does not share any resources with other cloud environments. This means that clients can access the analysis environment or industrial devices within the plant at a level of security and performance on a par with an on-premises solution. - Provides data and device management features gathered from various PLCs/CNCs

IIJ is building its systems in cooperation with Advantech Co., Ltd., whose WebAccess data gathering software supports over 250 different kinds of PLC and CNC equipment both within Japan and abroad, and with Nippon RAD Inc. for a solution that supports a multi-vendor environment. IIJ IoT service platform sits between industrial PCs and the cloud, and it offers data and device management features that include the management and remote monitoring of the SIM cards equipped in industrial PCs. It also adds attribute metadata to the gathered data, such as plant number, line number, product name, and the department in charge

Overview of the IoT System

For new production lines, IIJ has built a comprehensive IoT platform that handles data collection and analysis from network edge nodes, compiling data on equipment operating state and power usage. Moving forward, to make it possible to optimize features such as preventive detection through forecasting, it will work to make production lines even smarter-for example, by comparing the results of sampling inspections of production components and the operating status of production lines in order to identify the cause of any signs of problems in an early stage, and by forecasting machine tool usable life and the appropriate time to replace machine tool parts.

The current IoT system roll-out targets roughly 370 machines on the new production line, generating approximately 30,000 data points. It is planned to steadily expand the number of targeted machines and the types of data gathered.

- Ascertains the current operating state of the equipment

Uses mobile communications to obtain data about normal operations and any abnormal events on each of the facilities and lines from the PLC and CNC units that control the machine tools. Increases the speed of decision making by sharing real-time data via a dashboard. - Measures power consumption

Gathers data to help users determine the power usage of each of the facilities and lines branching off the power distribution board, thereby reducing power consumption. - Remote access

Utilizes closed mobile communications to allow users-right from their offices or other locations-to remotely control data transmission or to reboot industrial PCs without having to be on-site.

IIJ plans to engage in the following efforts:

- Collating the results of sampling inspections and equipment operating data

Collate the measurement results of production part sampling inspections and facility and production line operating data to analyze and ascertain equipment states when abnormalities are detected. - Predictive management of equipment

Use equipment state data to determine efficient measures and timing for handling machine tool issues and parts replacements. - Optimizing the IoT network security environment

Maintain constant monitoring of IoT network communications by installing FSEG(*) security software, and when any malware infection is detected in a device, automatically apply a security policy (such as increased monitoring or quarantining). - Utilizing local 5G

Implement local 5G as an in-house wireless communications environment instead of a Wi-Fi network. This makes it possible to more flexibly put together a production line by connecting more equipment and systems to the IoT network. This should also improve operations efficiency by interconnecting with client devices.

- (*)FSEG: Software developed by IIJ that implements network security measures. Maintain constant monitoring of communications between devices, and automatically apply various security measures as defined by the network administrator's security policy.

System image

IIJ will keep going to push forward the customers' smart manufacturing with its services and solutions related to IoT.

Endorsement

We are delighted to partner with Internet Initiative Japan (IIJ) in providing a closed-network IoT system at Toyota Motor Hokkaido's factory. In collaboration with the people directly involved in parts delivery, we ran a project that introduced WebAccess, a centralized collection of PLC and CNC device data. We adopted APAX, an industrial computer that saves control panel space.

To help our clients promote the IoT, we intend to continue supporting the installation of ECUs, high-performance industrial gateway devices, and LoRa wireless vibration sensors.

Takaaki Furusawa

General Manager, Industrial IoT Business Division

Advantech Co., Ltd.

Nippon Rad warmly congratulates Internet Initiative Japan (IIJ) for initiating an IoT system on the new production line at Toyota Motor Hokkaido. We are delighted to have been able to contribute-together with IIJ and our partner Advantech-to the construction of a closed mobile IoT network platform, a technology that is increasingly garnering more attention. We were able to fully demonstrate the expertise we have gained in building frameworks and aiding installations.

We intend to continue collaborating with IIJ and acting as a wide-ranging solutions integrator for smart factories.

Michimasa Suzawa

Representative Director, President

Nippon Rad Inc.

About IIJ

Founded in 1992, IIJ is one of Japan's leading Internet-access and comprehensive network solutions providers. IIJ and its group companies provide total network solutions that mainly cater to high-end corporate customers. IIJ's services include high-quality Internet connectivity services, systems integration, cloud computing services, security services and mobile services. Moreover, IIJ has built one of the largest Internet backbone networks in Japan that is connected to the United States, the United Kingdom and Asia. IIJ was listed on the First Section of the Tokyo Stock Exchange in 2006.

- For more information about IIJ, visit the IIJ Web site at https://www.iij.ad.jp/en/.

The statements within this release contain forward-looking statements about our future plans that involve risk and uncertainty. These statements may differ materially from actual future events or results.

- For inquiries, contact

-

IIJ Corporate Communications

+81-3-5205-6310

+81-3-5205-6310  +81-3-5205-6377

+81-3-5205-6377  press@iij.ad.jp

press@iij.ad.jp

- (*)All company, product, and service names used in this press release are the trademarks or registered trademarks of their respective owners.

- Related Contents

End of the page.